|

Welcome to the Reel Boating Forum.

From Trailer Boaters to Captains to Marine Industry Professionals, the Reel Boating Forum welcomes you to join in with other boaters and fishermen discussing topics including sportfishing, marine electronics, boating safety, boat engines and more. Use our FREE boat classifieds to sell your boat or fishing gear. Marine Industry Vendors are also welcome to register a username and freely post their products or services |

kerno

-

Posts

91 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by kerno

-

-

Adding a water pickup on the hull itself worked very well on several of my fast boats and let me use hydraulic jack plates to raise the engines way up without running the water pumps dry. But it only works in smooth water when the hull remains in contact with the water's surface. For something like this race, I'd rig the pickup to feed a livewell or large sea chest, so the pumps continued to get water even when the boat was airborne. Hull pickups can generate huge amounts of water pressure, so you can let the lower unit pickup water under normal running and leave the stock water pump in place. As long is there is a check valve in the feed line, the hull pickup(s) will take over at speed. The water pressure at 70 mh is 70 PSI and there is enough volume going backward into the pump that the impeller will stay wet and not burn up.

-

The job of the trim tabs is to shift the weight of the boat. The force on the tabs is the same, no matter if it is a lot of force on a small area or less force distributed over a larger area, the force seen at the end of the piston is the same. Big tabs halfway down are equal to small tabs all the way down.

-

Sorry, I misunderstood what you are missing. Some hubs have a sheet metal cover that covers the bearing nut and are then locked in place with a cotter pin. They are usually used with non castellated nuts. If you've replaced the original nut with a castle nut and the cotter pin installs properly, you should be good to go without the sheet metal cover.

-

If I recall correctly, the Bennet tabs have a very simple hinge that is really just a bent flange. If you take oneoff and take it to a decetn industrial sheet metal shop, they should be able to duplicate them while making them longer and wider. I had a set made like that once and had them turn a one inch flange down on each side that helped containthe water and kept the spray down a little while making the tabs stiffer. Type 316 is the best stainless to use, buit 302/304 is OK as well. Be sure to have the passivated or electropolished before you install them or they will rust, even if made out of stainless.

K-planes work well,but I even made a set of them bigger!

-

The covers come in several different sizes. Your best bet is to look for a Bearing Buddy. But measure first, since they come about 1 3/4", 2", 2 5/16" and 2 7/16" diameter. You can find 'em on eBay.

-

I must have missed the part in the manual about a pressurised supply, because my Jabsco head works great sucking right off the fresh water system. As Chris suggested, run a 1 inch hose from the output of the jabsco pump to your waste tank. The waste tank needs to be at least 8 gallons to be safe. If you can see it to check the level, great. If not, the Snake River capacitive system works well for monitoring the level. I have a tee in the outlet of my holding tank. One hose goes to the vacuum clean out port and the other goes to a Whale Gulper macerating pump. When I am where I can legally dump, I open the seacock, turn on the pump and drain the tank. Unless you know the overboard macerating pump is there, the system appears to be only emptied by pump out, since there is no Y valve. I use fresh water because sea water makes holding tanks stink like crazy. A charcoal filter on the vent line will help if the smell does become a problem.

-

I think its an excelent product, especially for anyone that goes out on the water alone on a regular basis.

Chris: We all read about the guy who fell overboard last week and damn near died. He wound up in the hospital and the boat wound up on the beach. I'll bet he buys one before he goes out alone - and we all do - but we're really careful, aren't we......

I bought Sospenders for my solo trips, but both me and the folks at home like the AutoTether.

-

-

Like everyone else, I've known I should of had one all along, but I never really look forward to wiring in and installing a new electronic device. I was seriously wrong about this one. The thing has its own batteries and installation consists of of using double sided tape to stick the module near the key switch.

I wondered how they integrated it into the wiring system. They don't. It comes with a little lanyard end that replaces the one on the existing kill switch - the one we all leave hanging there and never attach to anything. The new lanyard has a little electric plunger in it, so if it needs to kill the engine, it simply pushes the plunger and the clip comes out of the kill switch. Sweet and simple! I like it!

-

When Yamaha brought the F225 out in 2001, Mercury was well invloved with the Verado project, but knew it would be some time before they were ready to market. The made an agreement with Yamaha to buy F225's in Mercury colors and with Merc serial numbers, so they would have a good sized four stroke to sell, since Honda's 225 was released about the same time. That arrangement lasted until Mercury released the Verados. The advantage of the F225 is that both Yamaha and Mercury dealers have parts and supplies for the engines.

-

What are the dates? There's been unending talk about it, but I have never found out when in actually happens.

-

Auto parts stores or body shop supply stores should be able to order it for you.

-

They'll be using a sealer, but ask them to use 4200 instead of 5200. The difference is you can remove 4200, but 5200 requires things like C-4 to break it loose.

-

I looked at the shape of the bow and the deadrise. You'd need to sea trial it to be sure, but it is not a hull I'd buy if you had back problems or weak knees. My guess is that after 5 minutes on that boat into a head sea, you'd be on the cell phone trying to charter a helicopter to get you off it.

-

Easy fix: Add the wedges. They are cheap and they work. Make sure to seal the bolt holes well, so no water can get into the transom.

-

We don't usually have the problem in Hawaii, in spite of the weather being somewhat similar to Florida, but without the high humidity. Last week, the current owner of my Stamas 29 had me look at a poblem he was having with the boat and I crawled into the bilge. It had been a Florida boat, but 5 years ago, the bilge was bright and sparking white after I cleaned and detailed it. But I was stunned to see that it looked like somebody had taken flat black spray paint to it. Everywhere I looked, the surfaces, hoses and wires were the same charcoal grey. My Venture 34 has been here about a year and was also a Florida boat. It had been stored under cover, so there was very little mildew on it, but I'm not looking forward to the spread.

The big difference is that I always kept a fitted boat cover on the Stamas when I owned it. The new owner uses it for charters, so it is out almost every day and the cover has not been on it for a long time. I know mold likes humidity, so I am hoping that storing my Venture in the garage will prevent the problem, but am sure looking for hints and suggestions on how to slow it down.

-

I think you'll find universal agreement that the larger Whalers do a lot of good things, but a good ride is not on the list. You could speculate forever on why Whaler would do that, but I suspect that after the buyout, they figured their reputation was strong enough that people would buy them just because they were Whalers. If you are not concerned about the ride, they have a strong following and decent resale.

-

I've had to chase the threads on several SeaStar helms and they've all been stainless with a 5/8-18 thread on them. I'm not much of a SeaStar fan, but I am waiting to hear what brand has an aluminum shaft.

-

You missed the best part of the application where it says that passing bad checks or welfare fraud are not considered "fraud" in applying for a TWIC card.

-

The thing is cutting 5/8 line? I think the fault has to lie in the combination gypsy. As you know, the teeth are supposed to hold the chain and the V below the teeth is supposed to grip the line. I supect the problem is the result of using 5/8 line in a 5/16 chain gypsy. The line cannot get deep enough in the gypsy to avoid the teeth of the chain portion.

Typically I'd expect to see 3/8 or 1/2 inch chain with 5/8 line. 1/2 inch line is common with 5/16 chain and I'll bet 1/2 sits deep enough in the gypsy to be protected. The ugly part is the Lewmar parts are stupidly expensive and a gypsy is on their solid gold list.

-

I thin I just decided what kind of charger I am buying next time. The one that croaked was a Guest. I e-mailed them abiut repair and never got an answer. Not good....

-

I have drilled and tapped cast alumium wheels for knobs. Ibelieve the Edson knob uses a 5/16-18 bolt.

-

As a builder, I am forever amazed at how any experts there are out there. It doesn't matter if it is the ridge beam or the sprinkler system, somebody is going to tell you what you are doing wrong. The real irony is the number of times the building inspector gets it wrong.

This week it was the electric company. They drew the distribution plan for the subdivision and accepted it when it was completely installed. But when we called 'em out to tie in the first house, they said the 3 foot by 5 foot box they specified was too small to do a splice in. I said there's only one house and only one splice. It turns out they wanted to run the street light out of the same box. I pointed out that there was no street light and the response was "Well, there might be if they ever widen the road." I don't know about your code, but we have to cover all conduit with at least 12 inches of concrete, so putting in a bigger box is not an easy or inexpensive task. You know who gets to pay for it.

-

I've learned never to count the total number of tires on things you own. It will keep you up at night and wonder how much of the National Debt is driven by tires........

I have three compressors!

Trim Tabs

in Boating and Fishing Discussion

Posted

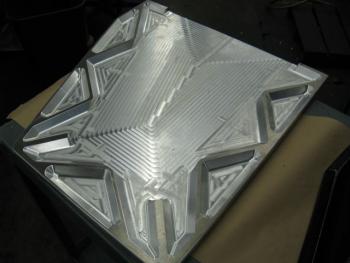

I have Mitsui Seikis and Fadals. We're using Gibbs software and an NC machine is a great toy to have! I hard anodized the tab extensions before I hung them.